Even the smallest brand can create clothes that look factory-made today. DTF technology Direct-to-Film has turned the idea of clothing production upside down. Previously, everything was different: large print runs, bulky equipment, expensive materials. Now there’s a film, a heat press, and a little inspiration. This is enough to print a design that will withstand dozens of washes and remain as vibrant as the day it was created.

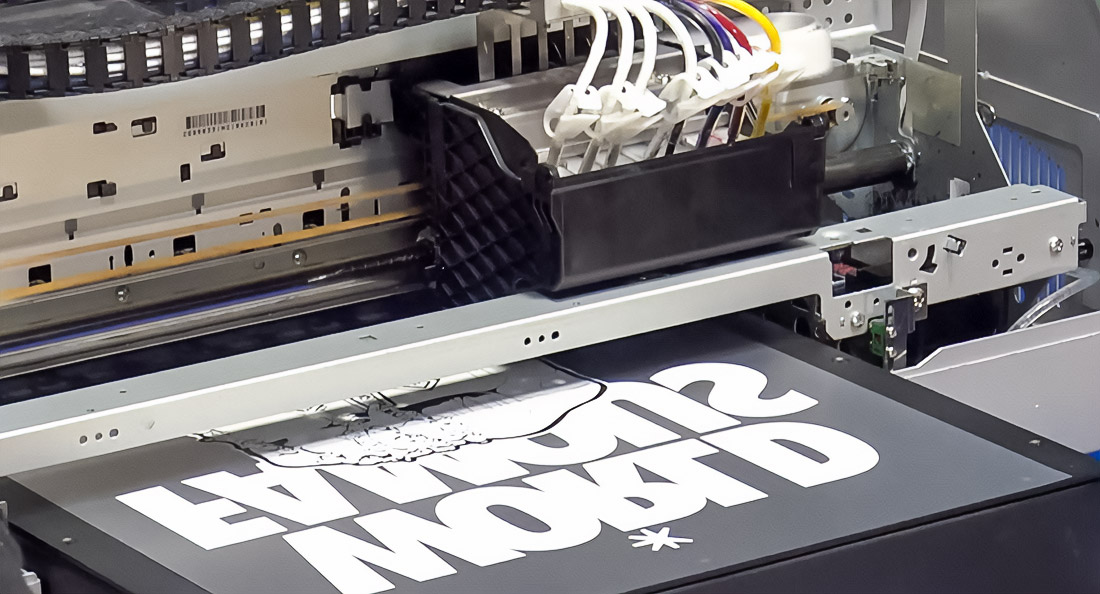

DTF printing is not just a way to transfer images. It is a process in which digital precision is combined with artisanal freedom. The image is printed on a special PET film, then coated with powder glue and transferred to the fabric under the influence of heat. It only takes a few minutes and you have a ready-made item in front of you. No screens, no pre-preparation, no extra cost.

Versatility And Speed That Change Everything

The main strength of DTF is its versatility. It works with cotton, polyester, nylon, leather, and blended fabrics. A designer can use one technology to create T-shirts, hoodies, bags, or baseball caps without changing equipment. The colors do not fade, the drawings do not crack even after fifty or more washes. The print remains soft and elastic, without losing its saturation. For a small brand, this is a sign of professional quality that helps retain customers.

Small brands value DTF for its flexibility. You don’t need to order hundreds of products to justify production. You can print ten T-shirts to test the idea. Did the customers like it? Finish another twenty. Didn’t you like it? Change the design. The entire system is based on the “print on demand” principle. There are no minimum orders, which means there is no risk of freezing money in unnecessary stocks.

Gang sheets are another trick. Multiple drawings are placed on a single film, saving material and reducing cost. As a result, every penny works for the brand. Testing, limited collections, seasonal drops all this has become easier. Young brands can now create capsule series with precision and speed that only large companies used to dream of.

Environmental Friendliness And Freedom Of Design

The eco-friendliness of DTF printing is not a slogan, but a fact. Water-based ink is used without toxic substances. The film is recyclable, and waste is minimal. Energy consumption is lower than that of silkscreen printing, and water is almost not consumed. Small brands that care about sustainable production choose this path. After all, environmental friendliness today is not about fashion, but about the customer’s trust.

DTF printing loves details. Photos, complex drawings, gradients, microtexts everything looks clear and vivid. No color restrictions. You can embody any idea, from minimalism to avant-garde illustrations. And if you add a little personalization, a name, a phrase, a unique shade the thing becomes not just clothes, but an expression of personality. For brands operating in the niche of custom fashion, this opens up huge opportunities.

Speed is another advantage. It only takes a few days from an idea to a finished product. This is a salvation for online stores, designers working with dropshipping, and brands that release new designs every week. You can quickly respond to trends: a TV series has been released, and the collection is ready in a couple of days. This is a real freedom of creativity, which was previously limited by the production framework.

Brands use DTF to reinforce style. Logos, inscriptions, brand patterns everything can be reproduced with perfect accuracy on any fabric. This helps to maintain a unified visual language, whether it’s a T-shirt, backpack, or hoodie. Reputation is made up of small things, and print quality decides a lot here.

Scaling up? Easy. You can start with a home thermal press and ready-made films, and then purchase your own printer with a resolution of 300 DPI. This print is not inferior to industrial designs. With proper care, products retain their shape and color for years. Durable, bright, flexible they survive dozens of washing cycles without losing their appearance.

DTF printing has changed the market. It broke down the barrier between large factories and independent creators. Now one designer can compete with a corporation. Small brands have the opportunity to act quickly, experiment, produce limited editions, and adapt to demand. The buyer wants uniqueness, and DTF gives it.

This technology has not just made life easier for businesses. It gave them independence. You no longer have to choose between quality and freedom. DTF makes possible things that previously seemed expensive, time-consuming, and complex. Now all you need to succeed is an idea, a print, and a little courage and if you’re looking to start locally, you can even find dtf printing near me to get your designs produced faster and with professional precision.

I graduated from the California Institute of Technology in 2016 with a bachelor’s degree in software development. While in school, I earned the 2015 Edmund Gains Award for my exemplary academic performance